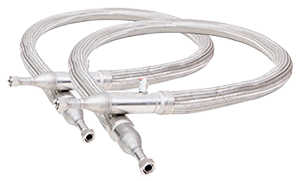

Paịpụ Cryogenic nke a na-eji ekpochapụ ihe mkpuchi (na-agbanwe agbanwe)

A na-etinye ya n'ime igwe hydrogenation na ọdụ hydrogenation

Paịpụ Cryogenic nke a na-eji ekpochapụ ihe mkpuchi (na-agbanwe agbanwe)

Okwu mmeghe ngwaahịa

Paịpụ cryogenic nke a na-etinye n'ime oghere (nke a na-agbanwe agbanwe) bụ ụdị paịpụ nnyefe etiti cryogenic nwere usoro mgbanwe, nke na-eji teknụzụ mkpuchi oghere dị elu na ọtụtụ ihe mgbochi.

Paịpụ cryogenic nke a na-etinye n'ime oghere (nke a na-agbanwe agbanwe) bụ ụdị paịpụ nnyefe etiti cryogenic nwere usoro mgbanwe, nke na-eji teknụzụ mkpuchi oghere dị elu na ọtụtụ ihe mgbochi.

Atụmatụ ngwaahịa

Ihe niile nwere ike ịgbanwe agbanwe ma nwee ike ịmịkọrọ akụkụ nke mbugharị ma ọ bụ ịma jijiji.

Paịpụ Cryogenic nke a na-eji ekpochapụ ihe mkpuchi (na-agbanwe agbanwe)

● Teknụzụ mkpuchi ọtụtụ oyi akwa dị elu nke na-anaghị amị amị, mmụba nke mmetụta mkpuchi, obere mmịpụta okpomọkụ.

● Njikọ dị mfe ma ọ bụrụ na e nwee mgbanwe nke nozzle ma ọ bụ ọnọdụ akụrụngwa.

Nkọwapụta

Nkọwapụta

-

Tube dị n'ime

-

-

Nrụgide imewe (MPa)

≤ 4

-

Okpomọkụ imewe (℃)

- 196

-

Isi ihe dị na ya

06cr19ni10

-

Usoro dị irè

LNG, LN2, LO2, wdg.

-

Ụdị njikọ nke mbata na mpụta

flange na ịgbado ọkụ

-

Ọkpọkọ mpụta

-

-

Nrụgide imewe (MPa)

- 0.1

-

Okpomọkụ imewe (℃)

okpomọkụ gburugburu

-

Isi ihe dị na ya

06cr19ni10

-

Usoro dị irè

LNG, LN2, LO2, wdg.

-

Ụdị njikọ nke mbata na mpụta

flange na ịgbado ọkụ

-

Emebere nke ọma

Enwere ike ịhazi usoro dị iche iche

dịka mkpa ndị ahịa si dị

Ihe atụ nke ngwa

A na-ejikarị paịpụ cryogenic nke a na-etinye n'ime oghere (nke a na-agbanwe agbanwe) eme ihe - usoro njupụta na iwepụ ihe ndị na-akwagharị; mgbanwe njikọ n'etiti tankị nchekwa na akụrụngwa mmiri cryogenic; mgbanwe n'etiti tubes siri ike na akụrụngwa mmiri cryogenic; ebe ndị ọzọ nwere ihe pụrụ iche chọrọ maka teknụzụ na usoro.

ozi

Iji ike eme ihe nke ọma iji melite gburugburu ebe obibi mmadụ

kpọtụrụ anyị

Kemgbe e guzobere ya, ụlọ ọrụ mmepụta ihe anyị anọwo na-emepụta ngwaahịa kacha mma n'ụwa site n'ịgbaso ụkpụrụ ịdị mma mbụ. Ngwaahịa anyị enwetawo aha ọma n'ahịa ahụ ma nwee ntụkwasị obi bara uru n'etiti ndị ahịa ọhụrụ na ndị ochie.